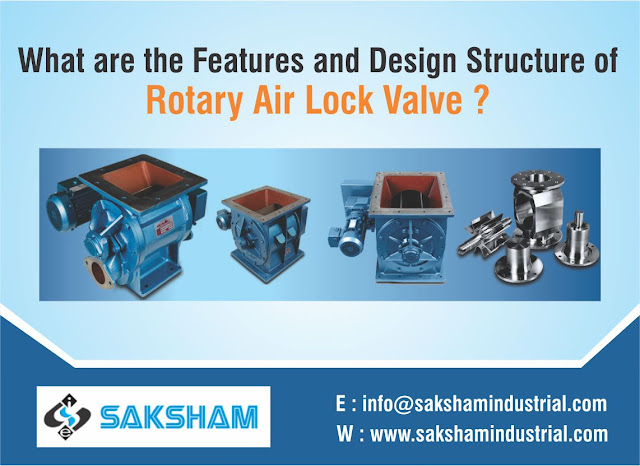

THE DESIGNS AND DEVELOPMENT OF ROTARY AIRLOCK VALVE

Rotary airlock valves are widely used device in material handling processes and convey material to maintain constant air pressure between inlet and outlet ports. This valve can operate as an airlock, feeder or combination of feeder airlock in a pressure conveying system. A rotary airlock valve acts as lock to the air where an air seal is needed between ports.

Design and Construction-

·

Rotary airlock valves have a heavy cast

housing which consist a body and two end covers, an internal rotating rotor and

drive package. The body has two parts an inlet and outlet that allow entering

the material and exit valve. The rotor shaft has multiple vanes and extends out

through the housing to external bearing that supported by end covers.

·

Inside housing, the vane radiate out from

shaft to the housing. The space between rotor vanes creates pickup material at

inlet port and transport to the outlet port. The drive package consist a

electric motors that connect to the rotor shaft by chain drive.

·

The end covers must be design to withstand

the pressure differential and machined to very tight. The rotor needs approx

eight or more vanes large shaft to prevent deflection, the rotor is precise

machined to fit tightly inside housing and the roughly thickness of a strand.

·

These tight tolerances minimize air leakage

and allow the rotor to rotate with minimal clearances.

Working principles-

Commonly rotary

airlock valves are used in industrial and agricultural applications as a

component in bulk materials handling. It included cylindrical endplates and

rotor with blade which mounted on a rotor shaft, and packing seals and

bearings. A rotor which supported by bearing it typically driven by an internal

combustion electric motor. The rotor shaft is turned to rotate inside housing,

at turn the rotor pockets which are space between blades.

The material

being handled the pocket at top through the inlet port and travel around in a

rotating motion and exit through the outlet ports.

Comments

Post a Comment